Building and testing Augustus taught me many hard lessons, including the importance of the center of gravity’s position, the proper design of a rudder, the consequence of excessive weight, and to name a few. Implementing what I had learned, I set upon constructing another 3-channel RC plane, Tiberius.

Lighter, longer and sleeker, its future was promising. This short blog describes the construction process and design decisions I made.

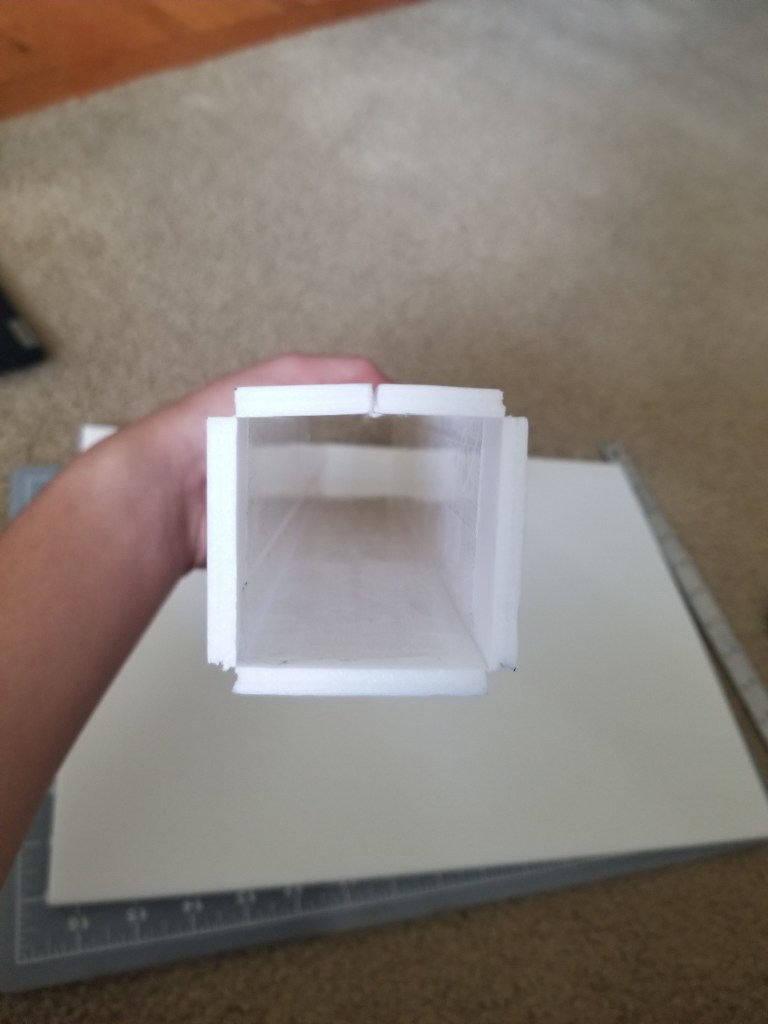

For the fuselage, I wanted to avoid the squished square design Augustus had, so while defining each side, I cut lines down the foam board that constitutes the fuselage but made both ends to be half a side. This way, they could be glued together in the middle instead of having to be glued with one side stacked over the other, as was the case with Augustus.

After reinforcing the fuselage’s interior with packaging tape, I glued the halves together, and a beautiful square resulted. Certainly a massive aesthetic improvement.

The length of the fuselage was constrained by the length of the foam board I was using, but I felt Augustus was too short. Therefore, I extended the fuselage by gluing a section of fuselage on one end while also ensuring the servo wires could still reach the receiver.

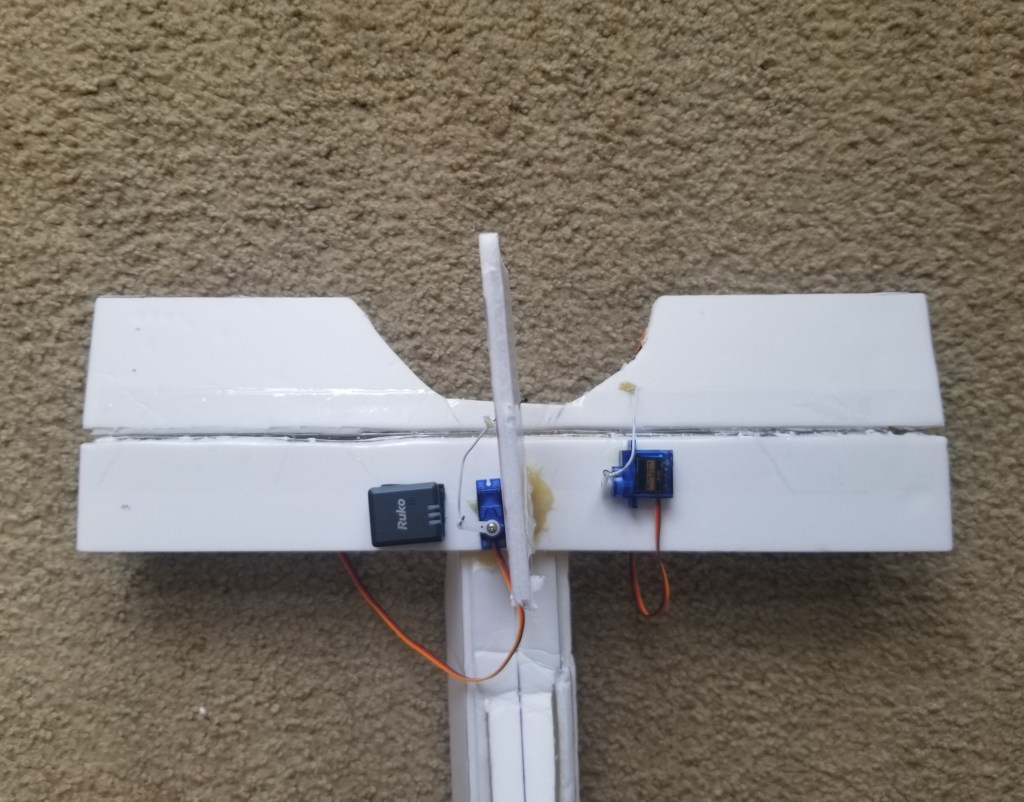

For the rudder, I looked at other designs that were more streamlined and copied them. The change was nothing terribly different; the new design just had a slant going back.

This rudder was then hot glued to the elevator, which I made larger and whose center I cut out so it wouldn’t hit the rudder at any angle.

This was then glued onto the rear of the plane.

As for the wings, they were reinforced with so much tape that no damage was present on the old ones, so I simply reused them.

Now, the motor case, the part that doomed Augustus to crash. The original was far too heavy. Constituted of five quarter-inch wood pieces, it totaled nearly 50 grams! To make it lighter, I got rid of three pieces, leaving just two squares glued to each other. This was also a big improvement.

This was then glued into the fuselage.

This all brings me to the motor—an unfortunate story that had a resilient recovery. You see, when screwing the motor on, I was informed by my brother that the last propeller had actually broken during Augustus’ crash.

This was really bad. With a packed schedule forecasted for the rest of the week, that morning was the only chance I had to fly.

Being resilient (/stubborn), however, I improvised a scrappy solution: My brother and I took the motor, propeller, and ESC from my Aeroscout and used them for Tiberius. This motor had no mount, so I screwed it onto the mount of the other motor.

This is not a decision I advise anyone to do, considering these parts were incompatible (indeed, I was forced to attach it with only two of four screws because the others couldn’t fit), but if SpaceX can put a Starship upperstage on a pad designed for a booster, I should be allowed to put a hobbyzone motor on a mount designed for an amazon motor.

The new ESC required a 3S LiPo battery, which is heavier than the 2S I was using, but the added weight is probably offset by the lighter motor and case.

With all of the exterior finished, the electronics were the last step. I connected the motor and ESC leads as well as connected the servos to the receiver. With one of the servos glued far from the center line of Tiberius, it kept leaning, so I put the GPS tracker on the other side to counteract it.

Finished!

This new RC plane had many improvements that could only have been found by first making and crashing Augustus. The improvements were largely on the design, but my process of building planes had also improved. Augustus took me weeks to build; Tiberius took me half a day to build. (I did stay up until 1 a.m. to finish it, however.)

Progress will continue as I scale the steep learning curve.

Ad caelum!